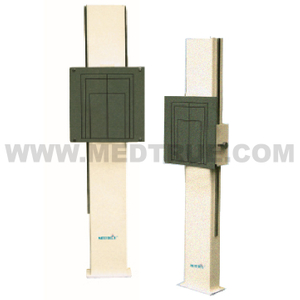

CE/ISO Approved Medical Automatic X-Ray Film Processor (MT01002A07)

This type is designed by the advantage technical in the world: The films is running in the three-point, so that the surface of the film won't be scar. After developing, the films will be very clear and have high quality. The machine is manufactured by the mold, the appearence is very beautiful, and the quality ls very steady. This type is suit for the small hospital and the client.

1. Developed film size: 5" x 7"~ 14" x 17"

2. Max. Developing width: 430mm(17")

3. Channed volume: Developer 4.3L, fixer 3.6L, water 3.6L

4. Developing speed: 180s

5. Developing temp: 28 CA35 C at option

6. Developing capacity: 50PCS/h( 12" x15")

7. Power source: AC220, 50/60Hz

8. Power: 1.5kw

9. Net weight: 40Kgs

10. Gross weight: 100kgs

11. Packing: 1050x830x710(LxWxH) All of our goods have 2 years guarantee time, when delivery the goods, our factory will put some easy-damaged parts in the package, so the customers won't worry about the repairing and after-sells service.

Product Characteristic:

* Produce technology: The out casing are made of plastics mould. It's very strong, durable and

Anti-corrode.

* Equipment Figure: New designed small body and taking films very expediently due films turn

Above.

* Install & Adjustment: Occupy small ground, install very freely, fit any dark room and put it on

The table directly.

* Film-Sending Frame: Safe Film-Sending systems come from one whole design, no films jamming

Or scratch.

* High-Effect Drying: New wind route technical can blow all little water spot on the films. At the

High net surrounding, can get distinct clear cut films.

* Film-sending Board With Cover: Light and close film-sending cover board, operator may open

Lamp and leave after enter films. This design make work easily and improve work effect.

* Critical Parts: The rollers' material can resist high-temperate and crystallization. No change

Shape and swell for using long time.

* Circuit Control: Microprocessor controls heating, automatic check and touch films, replenishing

Chemicals.

* Energy-Saving: It can save energy for max limit.